Kit Info

- Name

- FerroFacility 1000

- Model No.

- FerroFacility Kit 01 » The FerroFacility Series

- Description

-

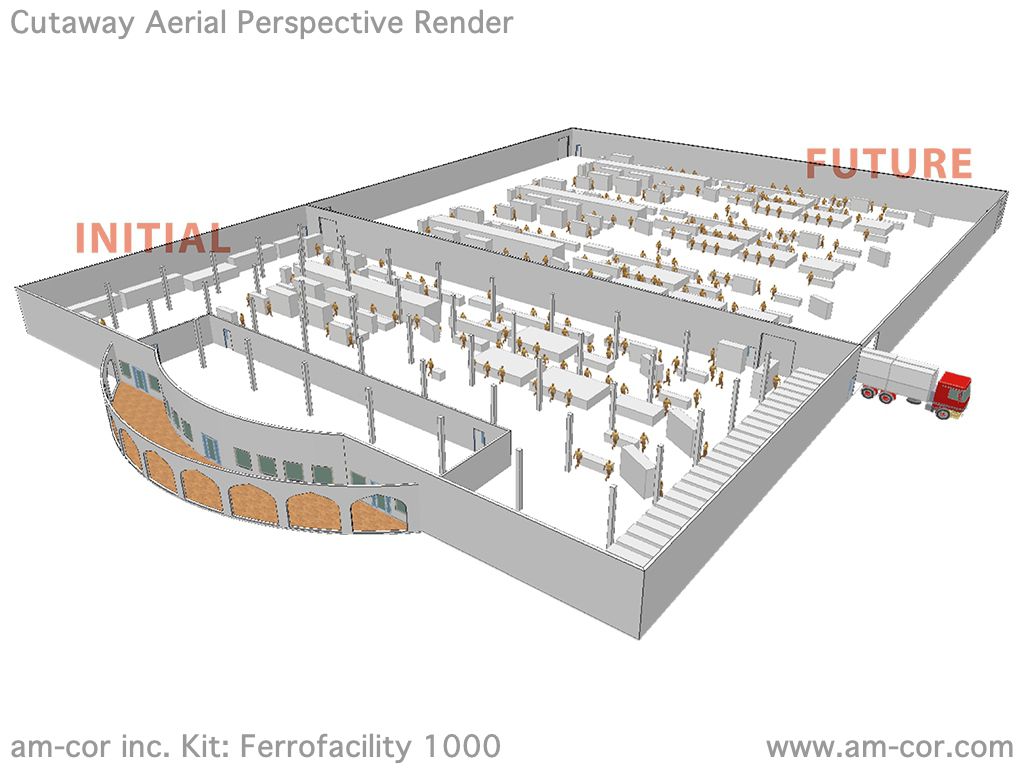

am‑cor FerroFacilities are production centers which manufacture building Kits using the patented am‑cor Ferrocement System. The am‑cor Unified Steel and Cement™ construction system is a unibody, disaster-resistant, durable & sustainable, minimal-maintenance building system. am‑cor Ferrocement building Kits are fast, economical, and easy to manufacture in am‑cor FerroFacilities. These building Kits are transported to the construction site, where they are quickly and inexpensively assembled into disaster-resistant, durable & sustainable, minimal-maintenance Ferrocement building shells.

Each FerroFacility is a customized, turnkey production package, ready to produce am‐cor Kits. Material & services include:

- Modern am-cor FerroFacility production center

- End-to-end construction, project management, and plant setup

- Shipping: FOB

- Off-grid renewable energy equipment

- Site assembly & Interior finishes

- Production & design equipment & machinery

- Training Programs: Production, design, and field assembly staff

- Factory-floor production management

The am‑cor FerroFacility is a Net-Zero modern marvel: each plant is a solar powered, off-grid, carbon-negative facility, using renewable energy to produce sustainable, affordable homes & buildings. All FerroFacilities are intelligently managed via internet cloud adminstration & management. They utilize energy-saving domotics and adapt to rapidly changing weather, market, and local events. Furthermore, FerroFacilities and can be built and operate in areas with little to no existing infrastructure.

FerroFacility Specs

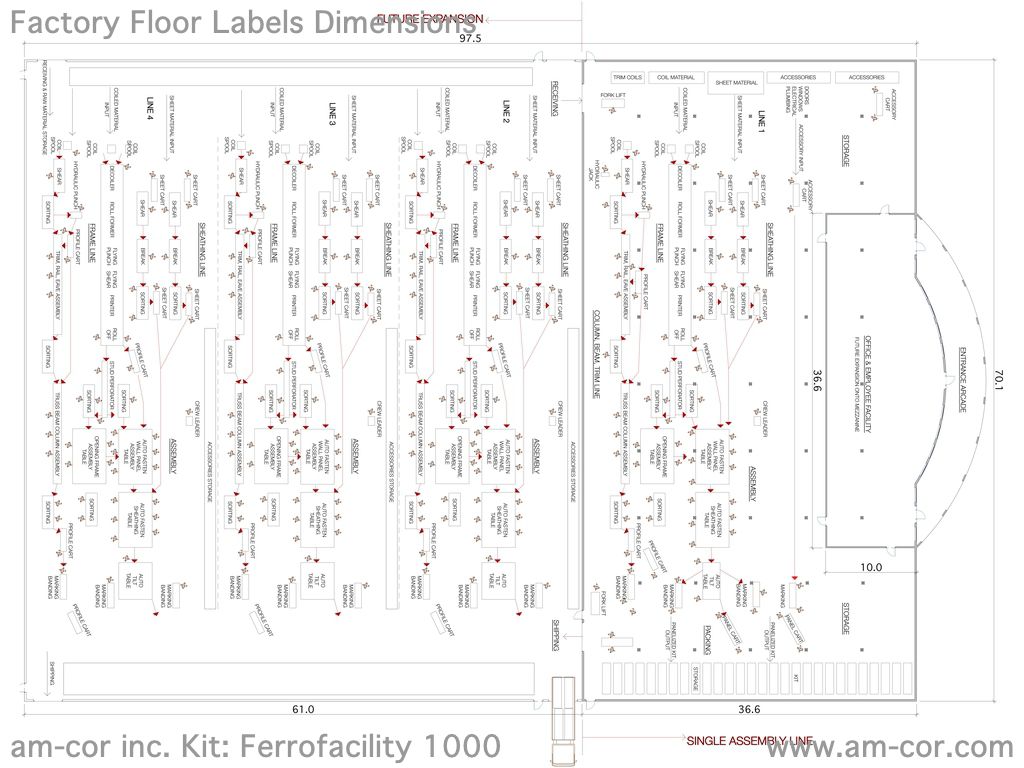

- Assembly Lines: 1 line, 1 shift (3 possible shifts)

- FerroFacility Building Area: 4060 m2 (43,050 sq.ft.)

- Avg. Building Kit Area Produced per line-shift per year: 100,000 m2 (1,076,400 sq.ft.)

- Avg. Building Panel Area Produced per shift per year: 500,000 m2 (5,382,000 sq.ft.)

- Building Kit Building Types Produced: All Types (residential, commercial, etc.)

- Estimated Annual Net Operating Profit: 14% ROI

- Estimated New Direct Employment: 140 Jobs per shift

- Material Required for Kit Production: Galvanized carbon steel coil, amcorite Ferrocement additive

- Material Required for Kit Assembly: Portland cement, sand & water (locally supplied)

Carbon Negative Zero‐Energy Production

- Off‐grid operation (no electrical/water hookup required)

- Solar generated power & hot water

- Wind & geothermal (where applicable)

- Energy‐saving domotics & smart grids

- Rainwater catchment

- Composting toilets (no infrastructure required)

- Green walls

- Sustainable plant design & management

- Producer

- am‑cor inc.

- Type

- Ferrocement building Kit

Additional Info

- Designer

- Macdonald Architecture & Technology

- Stock

- MTO: Made To Order

- Shipping

- Standard 20'/40' Flat bed, van or container

- Availability

- Setup in approx. 9 months

- Inquiries

- Contact us for purchasing or shipping estimates

- Questions

- See our Kit FAQ