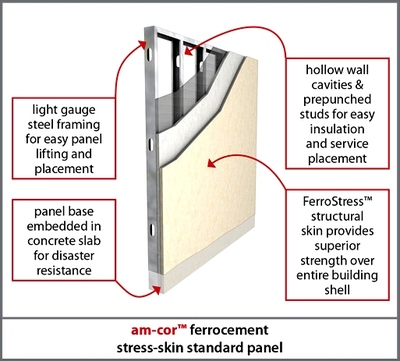

What is the am-cor System? It's a method of combining:

Into factory-made, Prefab building Kits.

Even better, not only are they easy & fast to put up, with no constuction skill required, but also provide sustainable & durable shelter from: hurricanes, tornadoes, earthquakes, bullets, and more.

Do you have a home, office, tinyhouse, or bunker to build? Whatever your building type, we've got you covered:

Check out our standard plans or bring your own design.

It's simple! We ship your Kit to your site, and you & your builder put it up fast:

am-cor Kits conform to: ASTM (American Society for Testing and Materials) standards, UL (Underwriters Laboratories) fire resistant assemblies, and the IBC (International Building Code)

Want to build all or part on your own? We're here for you.

The am-cor System was designed from get-go to make things easy for the average DIYer:

Need help with your loan? Contact us for info on financing & coordination with your bank/lender.

Ferrocement = highly reinforced, dense & thin steel & cement shells; originally used for boat hulls.

The am-cor System™ is a prefabricated, modern

Our standardized building panels are fabricated in a quality-controlled factory-setting. This simplifies: permit approval, shipping, and on-site assembly.

“We offer an advanced & green solution to today’s construction industry: Standard construction is just too expensive, time-consuming, and unsustainable. Worst of all it doesn't protect people from natural disasters, climate change, nor high maintenance & utility bills. Our Ferrocement am-cor System is the answer.”

- Angus W. Macdonald, Inventor & CEO

The am-cor System™ is a simple, fast, affordable way to build green & sustainable buildings. Architect Angus W. Macdonald invented and patented the am-cor Unified Steel & Cement Structural System™ after searching for a better alternative to standard construction methods. He wanted something that was simple to construct, quick to erect, cheap to build, and above all, beautiful, durable and sustainable.

The am-cor System is a proven system: am-cor structures have weathered tornadoes in USA’s Tornado Alley, hurricanes in the Caribbean, and floods on Virginia’s Eastern Shore. Our building shells are internationally code compliant, and have been approved by the US Army Corps of Engineers for construction in storm surge areas. The first structure was built in 1996, with numerous ferrocement homes and other buildings types worldwide. Its Ferrocement construction has withstood the test of time, with zero structural maintenance & minimal exterior maintenance.