Quick History

Ferrocement is the forgotten sister of standard reinforced concrete construction (both were invented & patented in France in the 19th century by Joseph Monier & Joseph-Louis Lambot). Reinforced concrete went on to be used for building, and Ferrocement was mostly used for boat hulls. Unfortunately, Ferrocement's use in construction was eclipsed by reinforced concrete. Architect Angus W. Macdonald developed a method of panelizing, prefabricating, and mass producing Ferrocement building components, called the am-cor System.

Ferrocement Construction

When usually used for construction, Ferrocement is often custom-formed on-site by hand, in a time-consuming and error-prone process.

Angus W. Macdonald's combination of advanced Ferrocement unibody construction with his preengineered, prefabricated, panelized production methods, results in a superior building construction system:

- Standardized for code approval, permitting, shipping

- Extremely Fast & Efficient

- Minimal Labor/Material

- Modern, Advanced Technology

- Affordable & Inexpensive

- Both Green and Sustainable & Resilient

Ferrocement & the am-cor System

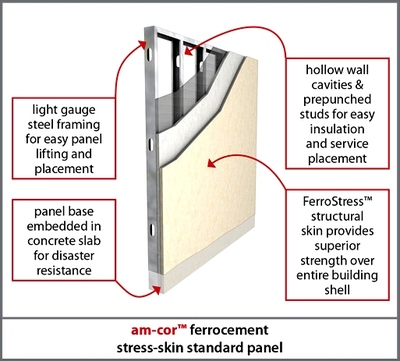

The patented am-cor Unified Steel & Cement System of construction uses Ferrocement extensively, both on a building component level and a structural level.

Key to the am-cor System's success:

- Advanced Ferrocement engineering, which allows for an extremely high strength-to-weight ratio, using much less material than standard construction

- Specialized amcorite™ structural cement additive, which allows very thin, integrated cement shells to act as disaster-resistant, high tensile, unibody Ferrocement stress-skins

- Ferrocement's considerably less material use = cheaper & faster to build with; smaller carbon footprint

The disaster resistant strength of the am-cor System emerges from its integrated, composite construction.

Structural Integration

The am-cor System features advanced, patented, Ferrocement technology. All building elements are unified by a monocoque, Ferrocement building skin – forming a single integrated structure.

- Walls, roofs, floors, stairs, balconies, etc. act as a single structural unit

- Eliminates need for separate structural elements or materials for walls, beams, columns, headers, etc.

- Does not rely on fasteners (nails, bolts, screws)

- Single material unibody construction eliminates need for complicated multi-material flashings, connections, and details

The composite construction of the unibody and monocoque structural building skin means:

- Greater structural strength

- 2-3 times the strength of reinforced concrete block masonry

- Uses 80% less material than reinforced concrete block masonry

- No fasteners = no weak points

- Patented FerroStress™ skin = disaster resistance, increased durability

- Outside forces distributed through structural stress skin and frame

- All outside forces are distributed through the amcorite structural stress skin to the internal galvanized steel frame

Composite Ferrocement Construction

- Combination of different materials, which together act as a stronger unit

- amcorite™ concrete and carbon steel mesh members form structural, highly reinforced stress skin

- Allows for both unibody and monocoque construction techniques

- Unibody = structural skin is integrated into a single unit with the frame, rather than a separate body-on-frame

- Monocoque = structural skin supports structural load, rather than internal frame with non-load-bearing skin

- Used in automobile and aircraft construction to provide stability and lightweight structural integrity

Resources

Inventor Angus W. Macdonald's works on Ferrocement:

- Ferro-Cement Coatings on Panelized Lightweight Steel Frame Structures, Ferro-7 Seventh International Symposium on Ferrocement and Thin Reinforced Cement Composites, 2001. M. A. Mansur and K. C. G. Ong, editors, National University of Singapore, Singapore, 415-420 - Contact us for a copy

- Architectural Details to Develop Affordable Disaster Resistant Structures Using Ferrocement Technology, Ferro-8 Eighth International Symposium on Ferrocement and Thin Reinforced Cement Composites, Bangkok, Thailand, 2006 - Contact us for a copy

- Affordable Ferrocement Housing, 2017, Angus W. Macdonald M.Arch. AIA Architect

- Innovations in Ferrocement, Keynote Address: Fourth National Convention of the Ferrocement Society of India, Kerala, India, 2017

- Designing for Disaster Resistance, American Institute of Architects: Architecture Exchange East Symposium, 2018 Richmond, VA USA

- am-cor Disaster Resistant Emergency Reconstruction, 2018, Angus W. Macdonald M.Arch. AIA Architect

- Steel Building Kits, 2010 - Interview with Angus W. Macdonald

External resources:

- Practical Ferrocement Classes at the Ferrocement Educational Network - Many thanks to Director Paul Sarnstrom for his efforts over the years!

- Wikipedia's article on Ferrocement

- Very informational paper on Ferrocement by L. Robles-Austriaco