Overview

Why is the am-cor Ferrocement Construction System considered Green & Sustainable?

- Ferrocement = truly sustainable & low-carbon footprint construction material produces approx. 70% less carbon than standard reinforced concrete masonry

- Approximately 70% less material = 70% of construction value as Carbon Credit

- Steel & cement materials = 100% recyclable (95% of the steel content is currently recycled)

- No scraps or construction waste with an am‑cor structure = Less environmental impact

- Less site disturbance decreases environmental impact

- Lower transportation cost: 70% lower material requirement reduces fossil fuel consumption

- am‑cor panelized structure creates no site waste or transportation to remove and dispose of waste

- The am‑cor System's Disaster Resistance virtually eliminates replacement cost

- am‑cor extreme durability extends building shell life cycle, reducing unit life cycle cost

- No VOCs (Volatile Organic Compounds) exist in am‑cor structures = elimination of VOC health concerns

- Ant, termite & vermin resistance eliminates need for termite soil treatment and use of other poisons

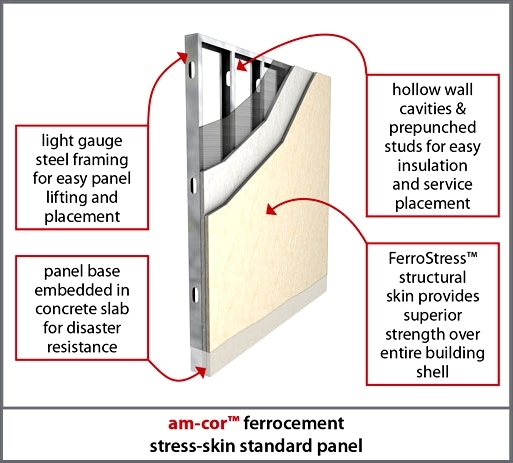

- am‑cor hollow cavity wall & roof construction allows for easy insulation = high energy efficiency

- Ferrocement base materials: cement & steel, are widely available both in raw and manufactured form worldwide

Resources

Durable

There are 3 reasons for the am‑cor System's extreme durability:

- Galvanized steel and cement are two of the strongest, most durable materials known.

- The am‑cor System's composite & integrated Ferrocement design combines galvanized steel and cement together structurally, unifying them to make them even stronger: this extra strength contributes to the am‑cor System's life-saving disaster resistance & durability comparisons.

- Most structural deterioration is due to water penetration; the seamless amcorite Ferrocement skin providers strength & lifelong protection from deterioration.

Sustainable

The basic materials used in the am‑cor Unified Steel & Cement System are created from two of the most prevalent minerals on earth: Iron and Silicon. These minerals are available worldwide.

However, it takes high heat to manufacture steel and cement from Iron and Silicon. Structures built with the am‑cor System require approximately 70% less steel and cement than standard construction; therefore, use of the Ferrocement am‑cor System reduces Carbon emission associated with concrete and steel construction by at least 70%.

Widespread use of am‑cor Ferrocement technology would significantly reduce man's overall Carbon footprint and help mitigate global warming.

LEED

The am‑cor System provides the following LEED points for your construction project:

- SS Prerequisite 1: Construction activity pollution prevention

- Prevent loss of soil during construction by stormwater runoff and/or wind erosion, including protecting topsoil by stockpiling for reuse.

am‑cor System construction does not require extensive site disturbance, thereby reducing runoff, as opposed to normal masonry and steel construction. - Prevent sedimentation of storm sewer or receiving streams.

The am‑cor System prevents sedimentation by reducing site disturbance during construction. - Prevent polluting the air with dust and particulate matter.

The am‑cor System does not outgas or pollute the air; amcorite cement products are wet-mixed to reduce heat island effects.

- Prevent loss of soil during construction by stormwater runoff and/or wind erosion, including protecting topsoil by stockpiling for reuse.

- SS Credit 7.2: Heat Island Effect

- Use roofing materials having a Solar Reflectance Index (SRI) equal to or greater than the values in the table below for a minimum of 75% of the roof surface.

The am‑cor System's Ferrocement roof skin allows for easy installation of highly reflective roofing to reduce the heat island effect.

- Use roofing materials having a Solar Reflectance Index (SRI) equal to or greater than the values in the table below for a minimum of 75% of the roof surface.

- EA Credit 1: Optimize Energy Performance

- Achieve increasing levels of energy performance above the baseline in the prerequisite standard to reduce environmental and economic impacts associated with excessive energy use...Demonstrate a percentage improvement in the proposed building performance rating compared to the baseline building performance rating per ASHRAE/ IESNA Standard 90.1-2004 (without amendments) by a whole building project simulation using the Building Performance Rating Method in Appendix G of the Standard.

The am‑cor System's amcorite seamless Ferrocement skin eliminates air infiltration. Other systems such as ICF, SIPS, etc., are tied to a single type of insulation product; in comparison, the am‑cor System is flexible, and allows for easy installation of high performance, environmentally-friendly insulation & thermal breaks for lower energy consumption: see our Insulation section.

- Achieve increasing levels of energy performance above the baseline in the prerequisite standard to reduce environmental and economic impacts associated with excessive energy use...Demonstrate a percentage improvement in the proposed building performance rating compared to the baseline building performance rating per ASHRAE/ IESNA Standard 90.1-2004 (without amendments) by a whole building project simulation using the Building Performance Rating Method in Appendix G of the Standard.

- EA Prerequisite 2: Minimum Energy Performance:

- Establish the minimum level of energy efficiency for the proposed building and systems.

In contrast with other systems such as ICF or SIPS, the am‑cor System's cavity walls and decoupling of insulation products from the building's structure allows for flexible & low-cost insulation solutions, resulting in high R value envelopes.

- Establish the minimum level of energy efficiency for the proposed building and systems.

- MR Credit 2.2: Construction Waste Management: Divert 75% From Disposal

- Divert construction and demolition debris from disposal in landfills and incinerators. Redirect recyclable recovered resources back to the manufacturing process. Redirect reusable materials to appropriate sites...Consider recycling cardboard, metal, brick, acoustical tile, concrete, plastic, clean wood, glass, gypsum wallboard, carpet and insulation.

The am‑cor System's precut, pre-engineered, and prefabricated Ferrocement Kits produce no on-site waste nor scraps; any excess material from ons-ite modifications is inert and easily recycled (metal, cement, etc.).

- Divert construction and demolition debris from disposal in landfills and incinerators. Redirect recyclable recovered resources back to the manufacturing process. Redirect reusable materials to appropriate sites...Consider recycling cardboard, metal, brick, acoustical tile, concrete, plastic, clean wood, glass, gypsum wallboard, carpet and insulation.

- MR Credit 3 & MR Credit 4.2: Materials reuse & recycle content

- Reuse building materials and products in order to reduce demand for virgin materials and to reduce waste, thereby reducing impacts associated with the extraction and processing of virgin resources.

The am‑cor System is composed of 95% recycled materials.

- Reuse building materials and products in order to reduce demand for virgin materials and to reduce waste, thereby reducing impacts associated with the extraction and processing of virgin resources.

- MR Credit 5.2: Regional Materials Manufactured Regionally

- Increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the use of indigenous resources and reducing the environmental impacts resulting from transportation.

Use of the am‑cor System maximizes use of local materials: sand, water, Portland cement.

- Increase demand for building materials and products that are extracted and manufactured within the region, thereby supporting the use of indigenous resources and reducing the environmental impacts resulting from transportation.

- EQ Credits 4.1 & 4.2: Low Emitting Materials

- Reduce the quantity of indoor air contaminants that are odorous, irritating and/or harmful to the comfort and well-being of installers and occupants.

The am‑cor System uses zero-emitting, non-toxic and zero-outgassing adhesives and sealants.

- Reduce the quantity of indoor air contaminants that are odorous, irritating and/or harmful to the comfort and well-being of installers and occupants.

- EQ Credit 5: Indoor Chemical & Pollutant Source Control

- Minimize exposure of building occupants to potentially hazardous particulates and chemical pollutants.

The am‑cor System contains minimal potentially hazardous particulates and chemical pollutants.

- Minimize exposure of building occupants to potentially hazardous particulates and chemical pollutants.

- ID Credit 1-1.4: Innovation in Design (exceptional performance)

- To provide design teams and projects the opportunity to be awarded points for exceptional performance above the requirements set by the LEED-CS Green Building Rating System and/or innovative performance in Green Building categories not specifically addressed by the LEED-CS Green Building Rating System.

The am‑cor System qualifies as an innovative use of durable green materials.

- To provide design teams and projects the opportunity to be awarded points for exceptional performance above the requirements set by the LEED-CS Green Building Rating System and/or innovative performance in Green Building categories not specifically addressed by the LEED-CS Green Building Rating System.