On-site Support

Your Kit comes with a site visit by one of our knowledgeable am-cor Field Reps, to instruct your crew & answer questions; e.g.: Ferrocement stuccoing.

💯 Code Guarantee

We guarantee our Kits conform to your local building code: from hurricane winds to heavy snow loads to UL fire ratings, you're safe with us.

Equipment Pack

Each Kit comes with a basic toolkit—screwguns, clamps, measuring tape, etc.—so you can get started ASAP.

Field Manual

An online, downloadable step-by-step guide for assembling your Kit, with structural details, arch. diagrams, photos and videos.

Less Waste

Since we prefabricate and precut as much as possible, our Kits have almost zero on-site waste. Your jobsite and the planet will thank you.

Warranty

We guarantee all our Kits are made to our higher than industry-standard quality control requirements, or we'll fix it at our cost.

How can the am-cor Prefab System help you?

Each am-cor Kit comes with:

Good news! All am-cor Kits are guaranteed to comply with IRC, IBC, and local USA building codes (2018 or later). In fact, all our materials are carefully specified to breeze through permit approvals & keep inhabitants safe:

The goal of inventor & architect Angus W. Macdonald was to rethink the entire building process from the ground up.

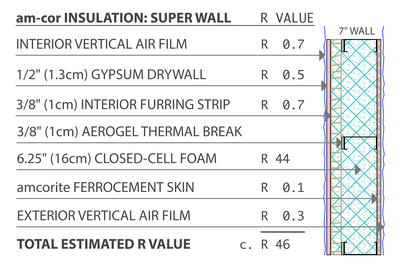

Looking for a resilient way to achieve Net Zero? Our standard spec. assemblies intelligently combine thermal properties of Ferrocement with modern insulation materials & practices:

Combining the above practices results in real-world high-performance off-grid residences—up to 6000 sq.ft. (560m2)—requiring zero energy for comfortable interior temperatures, as full-time homesteads for entire families & communities.

Let us take care of the hassle of framing and save yourself time, money, mess, and labor with our Prefab Kits.

am-cor Kits are efficiently manufactured in Culpeper, VA, USA in a factory setting with quality control, minimal waste, and a lower carbon footprint.

Ferrocement, aka structural stucco, is easy & simple to apply.

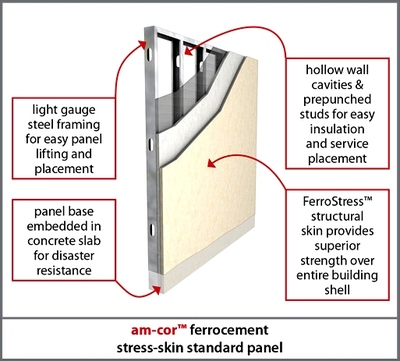

Your Kit's Ferrocement coat creates a unibody, hightly-reinforced, monocoque shell over the entire building, from Footer base to Wall top—and back down (Roof optional).

This continuous stucco stress-skin protects against disaster forces like fires, hurricane winds & flooding + as weather/rain shield, structural sheathing, wind bracing, etc.

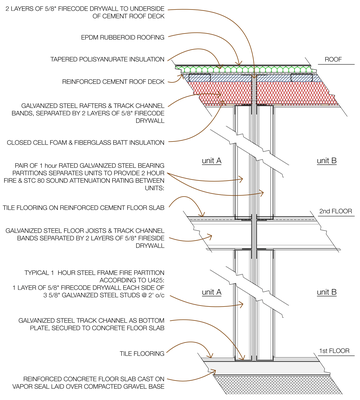

Overhead as well, our Prefab Kits are designed to be compatible with popular roofing products and standard installation methods.

Curious how to insulate the roof frame and under roofing? See our Insulation Solutions here.

Inside & outside, our Prefab Kits are compatible with regular finishes, popular products, and standard installation methods.

When we talk about the 100-year house, we mean it. Inventor & architect Angus W. Macdonald designed the am-cor System to save lives and protect inhabitants & property.

Using our Prefab Kits gives your buildings the high-quality and strength to be a real cut above standard construction.

We're happy to answer technical questions, get feedback, and hear about your projects!

The am-cor Unified Steel and Cement™ construction system is a disaster-resistant, durable and sustainable, minimal-maintenance building system. Buildings constructed using the patented am-cor Ferrocement System cost less to build, less to maintain, and less to heat and cool.

| Lower |

Use of the am-cor system significantly lowers construction cost, using:

|

| Less |

am-cor’s unique FerroStress™technology creates a continuous thin Ferrocement stress skin using amcorite™structural gel: am-cor buildings use 40% less material than standard construction, lowering material, shipping, and construction costs. |

| Less |

The am-cor System is panelized and pre-engineered; it obviates the need for a number of expensive and redundant building practices, reduces onsite errors, and lowers management costs & liabilities. |

| Less |

am-cor building are erected in days. am-cor projects are built in record time, without large crews, heavy machinery, complicated rigging, etc. Less time on site = Faster completion |

| Full |

In addition to panelization and pre-engineering, am-cor inc. provides full site support:

|

| Tried |

am-cor hotels, houses, villas, offices and casinos have weathered hurricanes, floods, tornadoes, and seismic events with no structural damage. The am-cor system provides higher quality for a lower price, balancing beauty with affordability. |

| A Green |

|

Let us know about your project!