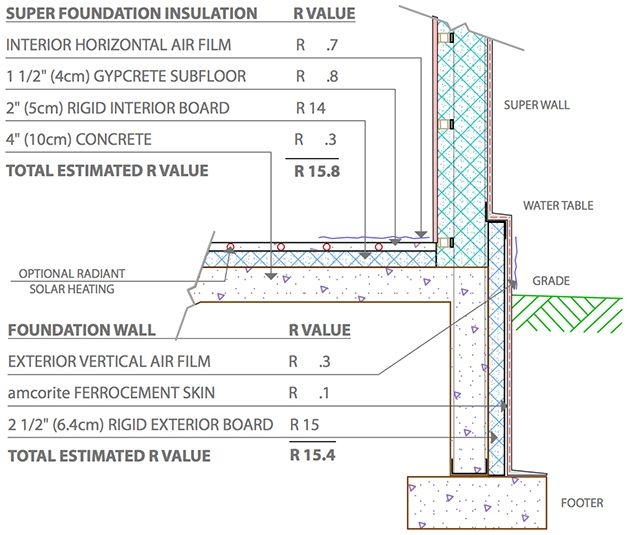

Foundation - Super

This is an example of a well-performing, affordable radiant floor & stem wall insulation assembly, and can be used with the Super Wall Insulation assembly above. All interior living spaces are insulated from the building's structural frame, and all insulation is encased in a seamless, weather-resistant coat of amcorite Ferrocement.

Disclaimer

NB: Details are not to scale, and may omit construction elements not relevant to insulation installation. Wall - Basic

Wall - Basic

This is the least expensive assembly which meets the minimum IBC & IRC code requirements. The outer surface of am‑cor walls is made of seamless amcorite Ferrocement. Because there are no junctions or gaps, insulation in am‑cor walls functions better than standard applications because the seamless Ferrocement skin eliminates air infiltration.Roof - Passiv

Superinsulation is a major part of the Passivhaus philosophy. Buildings built to the Passivhas specification have a lower carbon footprint, and require very little energy to heat or cool – consuming minimal fossil fuels or electrical power to create a comfortable environment all year round. Passivhaus designs often feature a complete unbroken thermal break between the inner and outer structures. Many European examples are framed with wood. This Passivhaus am‑cor roof utilizes an insulated ceiling space with an insulated drop ceiling cross frame separated by aerogel thermal breaks, and is framed in galvanized steel. This assembly eliminates thermal bridging from the building's structure to the conditioned interior.

Roof - Basic

Similar to the Basic Wall Insulation Assembly above, this Basic Roof Insulation Assembly with attic is an inexpensive assembly and actually exceeds the minimum IBC & IRC code requirements.

Example Roof Insulation Assemblies

You can mix and match different aspects of these roof insulation assemblies, to get the thermal resistance needed for your project.

Wall - Passiv

Wall - Passiv

Superinsulation is a major part of the Passivhaus philosophy. Buildings built to the Passivhas specification have a lower carbon footprint, and require very little energy to heat or cool – consuming minimal fossil fuels or electrical power to create a comfortable environment all year round. Passivhaus designs often feature a complete unbroken thermal break between the inner and outer structures. Many European examples are framed with wood. This Passivhaus am‑cor wall utilizes a double wall separated by aerogel thermal breaks, and is framed in galvanized steel with a galvanized Carbon steel Ferrocement coat. This assembly eliminates thermal bridging from the building's structure to the conditioned interior. Wall - Better

Wall - Better

This assembly exceeds building code requirements, and offers good performance at a relatively low cost. Its average R value is similar to the average functional R value of many SIPS, ICF, and other manufactured insulating wall panels. However, since the amcorite structural Ferrocement skin is seamless, there is zero air infiltration through the am‑cor wall. Air infiltration in normal walls reduces manufacturers' stated R values by up to 50%.  Wall - Super

Wall - Super

This super-insulated wall sample includes an inner framework for hanging finishes, separated from the am‑cor structural framework by Aerogel thermal breaks. The specified type of spray foam functions both as a vapor barrier and an excellent insulator. Its average total R value substantially exceeds both codes and most manufactured wall panel products. This assembly eliminates thermal bridging from the building's structure to the conditioned interior.Example Wall Insulation Assemblies

You can mix and match different aspects of these wall insulation assemblies, to get the thermal resistance needed for your project.

Overview

These are common insulation solutions, organized by cost, complexity, and performance. Example assemblies and material choices shown here should help you get started on the right insulation combination for your climate and your specific project requirements.

Preinstalled Insulation

In contrast to insulating wall panels, such as SIPS or ICF, the am‑cor System is first & foremost a structural system: by design, preinstalled insulation is not included in am‑cor Kits.

This allows you the flexibility to:

- Choose which insulation assembly is right for your project, budget, and lifestyle

- Swap in healthy alternatives to ensure low-VOC, high indoor air quality, and fire safety

- Achieve higher performance and a tighter building envelope with site-installed insulation (no joints = no air leakage)

- on-site insulation allows for concealed service runs (pipes & wires)

- Avoid environmental degradation caused by toxic polystyrene pellets/waste material blowing around your building site, onto neighboring properties, into waterways and generally disrupting the environment

See our FAQ entry for more information:

The am-cor System is a…

Healthy

- sustainably manufactured

- long-lasting (low-maintenance & non-degradation in performance)

- non-petroleum based

- don't support the growth of mold or mildew

- don't release toxins at room temperature over the product's lifetime (low-VOCs)

- don't release toxins in case of a fire (inert)

Insulation options we like:

ATTN Manufacturers: Do you provide a healthy, low-VOC insulation? We're interested! Please contact us so we can test your product with our assemblies.

Roof - Super

This superinsulated roof assembly can be used in conjunction with the Super Wall assembly by continuing the wall's inner finish framework along the roof frame interior. This assembly eliminates thermal bridging from the building's structure to the conditioned interior.